California-Abstract: Shaft parts occupy an important position in the field of machinery manufacturing, and its surface quality has a direct impact on the operational performance and reliability of the equipment. In this paper, the polishing method for shaft parts for in-depth discussion, analyze the advantages and disadvantages of various polishing techniques, and explore the application and development trend in the actual production.

I. Introduction

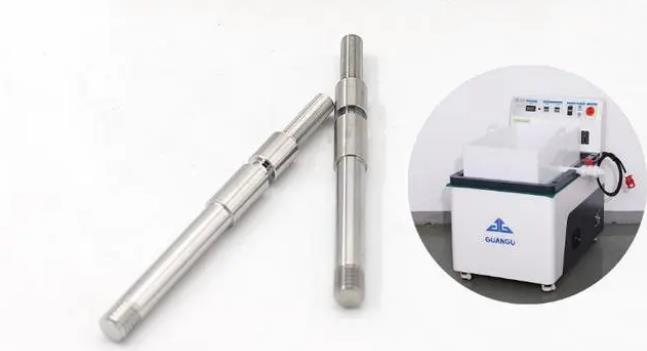

With the continuous progress of science and technology, shaft parts are more and more widely used in machinery manufacturing. The surface quality of shaft parts has become a key indicator of its performance. Polishing as an important means to improve the surface quality of shaft parts is of great significance to improve the overall level of China’s machinery manufacturing industry. In this paper, we will discuss the polishing method of shaft parts, in order to provide reference for actual production.

Second, shaft parts polishing methods and advantages and disadvantages of analysis

- manual polishing: manual polishing mainly relies on the operator’s skilled technology and experience, applicable to small quantities, complex shape or difficult to use mechanical polishing part. But manual polishing efficiency is low, labor intensity, and polishing quality by the operator’s skill level has a greater impact.

- Mechanical polishing: mechanical polishing can be divided into rough polishing, medium polishing and fine polishing three stages, applicable to large quantities, regular shape of the shaft parts. Mechanical polishing has a high productivity and stability, but the equipment investment is larger, the operation and maintenance requirements are higher.

- chemical polishing: chemical polishing through chemical reactions to make the surface of the parts to generate a layer of uniform, fine oxide film, thereby improving the surface quality. Chemical polishing is applicable to a variety of materials, shaft parts, but the complexity of the composition of the polishing solution, there is a certain degree of pollution of the environment.

- electrolytic polishing: electrolytic polishing using electrolyte solution in the electrochemical reaction, the shaft parts for polishing. Electrolytic polishing has a good polishing effect, high productivity advantages, but the equipment cost is high, complex operation.

Third, shaft parts polishing method in the actual production of applications and development trends

- For different production batches, part shape and material, choose the appropriate polishing method. For example, large quantities, the regular shape of the shaft parts can be mechanically polished; small quantities, the shape of complex parts can be hand-polished or chemical polishing.

- Continuously improve the polishing technology of automation, intelligence level. With the development of science and technology, automation, intelligent polishing equipment gradually replace the traditional manual operation, improve production efficiency and polishing quality.

- research new polishing technology and polishing materials. New polishing technology such as laser polishing, ultrasonic polishing, etc. gradually applied to the polishing process of shaft parts, improve the polishing effect.

- the development of green polishing technology. In the polishing process of shaft parts, pay attention to environmental protection, reduce pollution, research on green polishing liquid and polishing process, to achieve sustainable development.

IV. Conclusion

The choice and application of polishing methods for shaft parts are of great significance to improve their surface quality. In actual production, the polishing method should be reasonably selected according to the production batch, shape, material and other factors of the parts. At the same time, continuous research and development of new polishing technology and polishing materials to improve the polishing quality of shaft parts, and make contributions to the development of China’s machinery manufacturing industry.

Wechat

Wechat